-

Exploring High-Quality Brands of Chocolate Protein Bar Forming Machines in China: Quality and Innovation Leading Industry Development With the booming health food market, chocolate protein bars, a popular category combining nutrition and taste, rely heavily on the qualit...Read more »

-

The price difference of finger biscuit coating line (also known as biscuit dipping line, chocolate coating line) is very large, ranging from tens of thousands of dollars to hundreds of thousands of dollars. There is no fixed 'standard price' as it depends on multiple key...Read more »

-

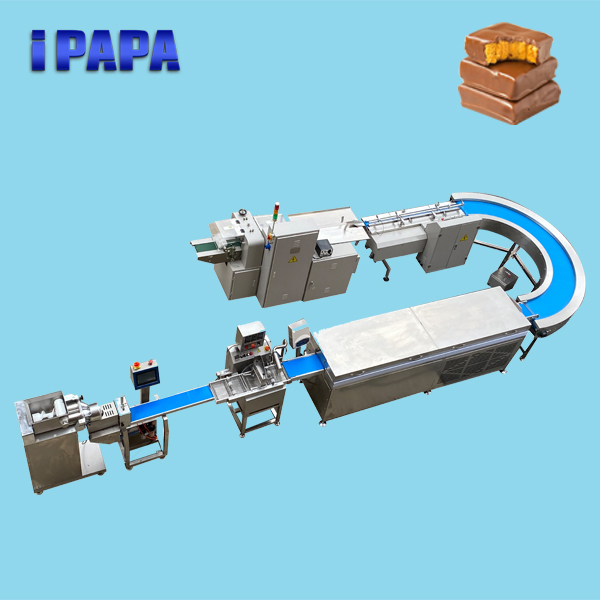

Chocolate coating machine is an industrial equipment specifically designed to evenly apply a layer of chocolate (or other similar coating materials, such as candy coating) on the surface of food or other items. Chocolate enrober is widely used in industries such as candy...Read more »

-

The price difference of protein bar manufacturing machines is huge, ranging from several thousand dollars to several million dollars. This mainly depends on the following key factors: Core factors affecting prices 1. Capacity of protein bar manufacturing machine (output...Read more »

-

Chocolate coating machines are specifically designed to handle the viscosity, melting point, and tempering needs of chocolate. Using them for sugar syrup coating is not ideal, and here’s why: Key Differences Between Chocolate and Sugar Syrup Coating: Feature Chocolate Coating Machines Sugar ...Read more »

-

The global protein bar market has surged in recent years, fueled by rising health consciousness, fitness trends, and the demand for convenient nutrition. But as entrepreneurs eye this booming sector, a critical question arises: Is the protein bar business truly profitabl...Read more »

-

The Energy Ball Forming Machine is an automated equipment designed specifically for producing Energy Ball type healthy snacks. It can quickly mix and press raw materials such as nuts, dried fruits, oats, seeds, protein powder, etc. into uniform spheres, and can be coated or decorated with additio...Read more »

-

1. Feeding system -Function: Transport the product to be coated to the processing area. -Composition: -Vibration disk/conveyor belt: Smooth conveying of products (such as cookies, soft candy) to ensure continuous feeding. -Sorting device (optional): Automatically arrange product directions to imp...Read more »

-

With the global fitness craze and the popularization of healthy eating concepts, the protein bar market is growing at a rate of 8-10% per year (according to Grand View Research data). An efficient protein bar forming machine can not only quickly enter this blue ocean mar...Read more »

-

The Need for Automation in Cereal Bar Manufacturing Challenges of Manual Production: Time, Labor, and Inconsistency Traditional cereal bar manufacturing involves labor-intensive processes that are not only time-consuming but also prone to human error. Manual production r...Read more »

-

On February 26, 2025, a delegation of well-known health food companies from Brazil visited our factory for a two-day on-site testing and technical exchange on the customized protein stick production line. This cooperation is not only a deep collision between the South American market and Chinese ...Read more »

-

With the rise of the global trend of healthy eating, cereal bars have become a popular choice for breakfast replacements, exercise supplements, and healthy snacks due to their rich nutrition, portability, and ease of consumption. One of the core technological equipment supporting the industrial p...Read more »