The price difference of protein bar manufacturing machines is huge, ranging from several thousand dollars to several million dollars. This mainly depends on the following key factors:

Core factors affecting prices

1. Capacity of protein bar manufacturing machine (output):

Small/laboratory/start-up level: produce tens of kilograms or hundreds of rods per hour. The price may range from several thousand to tens of thousands of dollars (e.g. small extruders, simple molding molds).

Medium scale production: producing several hundred kilograms per hour. The price range is usually in the tens of thousands of dollars.

Large scale industrial production: producing one ton or more per hour. The price can reach one million or even millions of dollars. This is usually a highly automated, continuous entire production line.

2. Automation level:

Manual/semi-automatic equipment: requires a lot of manual operation (such as manual filling of molds, manual demolding, and manual packaging). The price is relatively low.

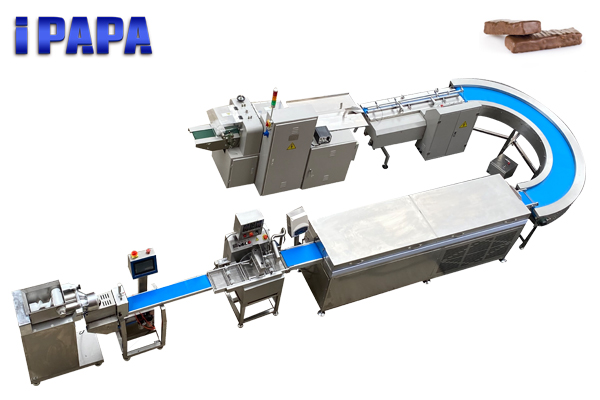

Fully automated production line: from raw material mixing, forming, cooling, coating (if applicable), cutting (if applicable), to packaging, all are completed automatically with minimal manual intervention. The highest price.

3. Equipment type and function:

Single function equipment VS whole line integration:

Buying only one mixer or tablet press is cheaper than buying a complete production line that includes mixing, conveying, forming, cooling, coating, cutting, and packaging. However, it is time-consuming and labor-intensive, and product weight and quality are difficult to guarantee, resulting in low production efficiency.

Molding process:

Squeezing/Extrusion Molding: The most common method is to extrude the mixed materials into strips through a mold and then cut them.

Compression molding: The material is laid in a mold and pressed into shape using a heavy-duty compression press (suitable for harder and denser bars). More suitable for products such as cereal bars, granolar bar,nut bar with a moderate price.

Coating function: If it is necessary to coat the protein stick with chocolate, yogurt layer or other coatings, additional coating machines (spray coating, dip coating) and matching temperature controllers and cooling tunnels are required, which will significantly increase costs. However, customers can expand more products and develop new ones.

Packaging function: Automatic packaging machines (such as flow packaging, pillow packaging, box packaging, etc.) are a major investment at the end of the production line.

4. Equipment quality and brand:

European brands such as B ü hler, GEA, etc. are known for their high quality, reliability, and advanced technology, and their prices are usually very expensive.

Chinese/Asian brands: Provide more price competitive options, such as PAPA Machine, with a wide price range that requires careful consideration of quality and after-sales service.

Used/refurbished equipment: The price is much lower than new equipment, but there are unknown risks, outdated technology, and difficulties in spare parts and after-sales service.

5. Approximate price range reference (new equipment)

Price range: $6000

Medium sized complete production line:

Medium capacity semi-automatic/entry-level automatic line (e.g. 100-500 kg/hr):

Price range: $30000- $50000 USD

High to medium capacity fully automated line (e.g. 500-1500 kg/hr):

Complete process: automatic batching/mixing, conveying, forming (extrusion/compression), cooling, online cutting (if required), coating (if required), automatic packaging (flow packaging/pillow packaging).

Price range: $80000- $100000 USD

Important Note

1. Energy bar manufacturing machine usually refers to the entire production line:

few single machines can complete all processes. The quotation is usually for production line solutions.

2. Hidden costs:

Installation and commissioning fees:

The cost of on-site installation and commissioning by supplier engineers may account for 1-3% of the equipment cost.

Spare parts:

In the initial stage, a certain amount of vulnerable parts and spare parts need to be purchased.

Training:

Operating and maintenance training costs.

Factory renovation:

It may be necessary to meet the water, electricity, and gas requirements of the equipment (compressed air, cooling water, special voltage), ground load-bearing capacity, spatial layout, etc.

Transportation and insurance:

especially for large imported equipment.

Tariffs and Value Added Tax:

Imported equipment incurs this cost.

3. The only way to obtain an accurate quotation is through inquiry: you need to provide the equipment supplier with as detailed information as possible:

Target product: Accurate formula description (ingredients, viscosity, particle size, water activity, etc.), final product size, shape, weight, structure (single-layer/multi-layer/coating).

Target production capacity: kilograms per hour or roots per minute (calculated by hour or year).

Automation level requirement: How many operators are needed?

Budget Range: Let suppliers know your budget constraints.

Venue limitations: available space, water and electricity conditions, etc.

In summary, without any specific production capacity, automation, or process requirements, it is impossible to provide an exact price. You need to start by clarifying your own needs and then inquire with multiple professional suppliers in order to obtain a meaningful quote. A small entry-level may only cost a few thousand dollars, while a large fully automated industrial line may require an investment of several hundred thousand dollars.

Post time: Jun-09-2025