With the global fitness craze and the popularization of healthy eating concepts, the protein bar market is growing at a rate of 8-10% per year (according to Grand View Research data). An efficient protein bar forming machine can not only quickly enter this blue ocean market, but also achieve long-term profitability through flexible production models.

1、 Market opportunity: The explosive logic of the protein bar industry

1. Rapid increase in consumer demand

-Fitness crowd: Over 2 billion sports enthusiasts worldwide rely on protein bars as portable energy supplements.

-Ordinary consumers: The demand for meal replacement drives the market, and the global market size has exceeded $5 billion by 2023.

2. High premium space

-The terminal selling price of ordinary protein sticks is about 3-5 times the cost (such as a raw material cost of $2 per stick and a retail price of $8-12).

-Customized products (such as vegetarian, low sugar, collagen) have higher premiums.

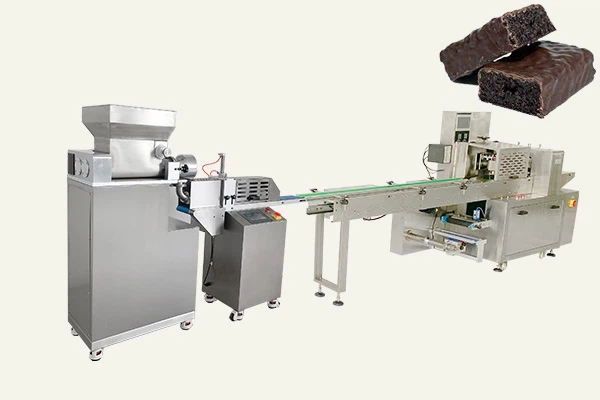

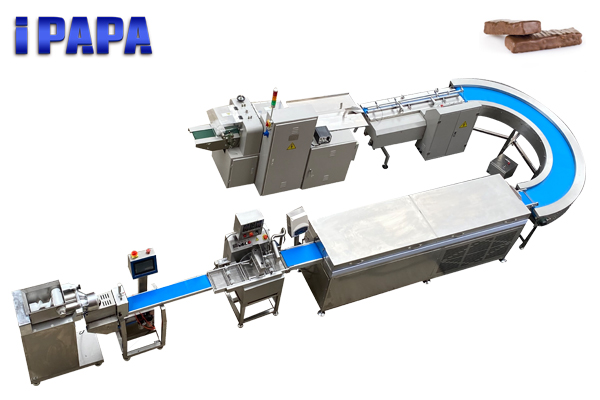

2、 Key investment parameters for protein rod forming machine

|

Equipment Type |

Capacity (kg/hour) |

Price Range (USD ) |

Applicable Scenarios |

|

50-100 |

0.5-1 |

Start up brand, small batch customization| | |

|

200-500 |

1-4 |

Large scale production, OEM outsourcing| | |

|

100-200 |

4-10 |

Multi formula switching, mid-range market| |

Calculation of Return on Investment (ROI)

Taking medium-sized equipment worth 200000 yuan as an example:

-Daily production capacity: 400kg in 8 hours → approximately 8000 pieces (50g per piece)

-Cost structure (calculated per unit):

-Ingredients: 1 USD (whey protein powder+nuts+sugar substitutes)

-Packaging: 0.5 USD

-Labor/energy consumption: 0.3 USD

-Total cost: $2.0 per unit

-Profit margin:

-Wholesale price: 4 USD/piece → Daily gross profit (4-2) × 8000=16000 USD

-Retail price: $8 per unit (self operated channel) → Double gross profit

-Return cycle: Equipment cost of $40000 ÷ Daily profit of $16000 ≈ 3 working days (excluding marketing and channel costs)

3、 Profit doubling strategy

4、 Risk Avoidance Guidelines

1. Certification threshold:

-Must obtain the * * SC food production license, with a 3-6 month approval period reserved.

-Export products must comply with FDA (US) or CE (EU) standards.

2. Inventory risk:

-Adopting the "production based on sales" model, using a molding machine to quickly adjust the formula and avoid backlog.

3. Competitive barriers:

-Develop exclusive formulas (such as adding chia seeds and probiotics) and apply for patent protection.

The core profitability of the protein bar forming machine lies in "equipment efficiency+precise positioning". Choose scalable models (such as reserved packaging module interfaces), focus on refining products in segmented markets in the initial stage, and expand the scale through automation in the later stage. It is expected to continue to reap dividends in the healthy food industry.

Post time: Mar-20-2025