Top Quality Tray Aligning Machine For Date Bar/Energy Bar/Fruit Bar - Double filling encrusting machine – Papa

Short Description:

Top Quality Tray Aligning Machine For Date Bar/Energy Bar/Fruit Bar - Double filling encrusting machine – Papa Detail:

Description:

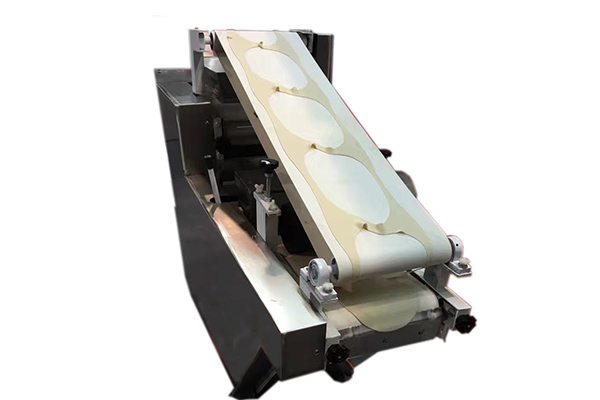

Automatic double filling encrusting machine is the upgraded machine of the standard encrusting machine,which has three feeding hoppers to make double filling products or double color products or double layer products.As usual,the machine can change different skin thickness, length, size of products.

Features:

1.Specially for making double filling or double color products.like cookie or mochi.

2.Easy to operate,PLC intelligent control system with colorful touch screen it has high-end configuration such as the Japanese Panasonic’s frequency changer,Taiwan electrical machinery ,to guarantee the machine stable operational performance.

Product detail pictures:

Related Product Guide:

Alto-Shaam Self-Cleaning Rotisserie Oven | Mini Meat Ball Machine

Traeger Grills Aren’t Technically Grills | Chocolate Machine Price

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Top Quality Tray Aligning Machine For Date Bar/Energy Bar/Fruit Bar - Double filling encrusting machine – Papa, The product will supply to all over the world, such as: Curacao , Dubai , Brazil , Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.