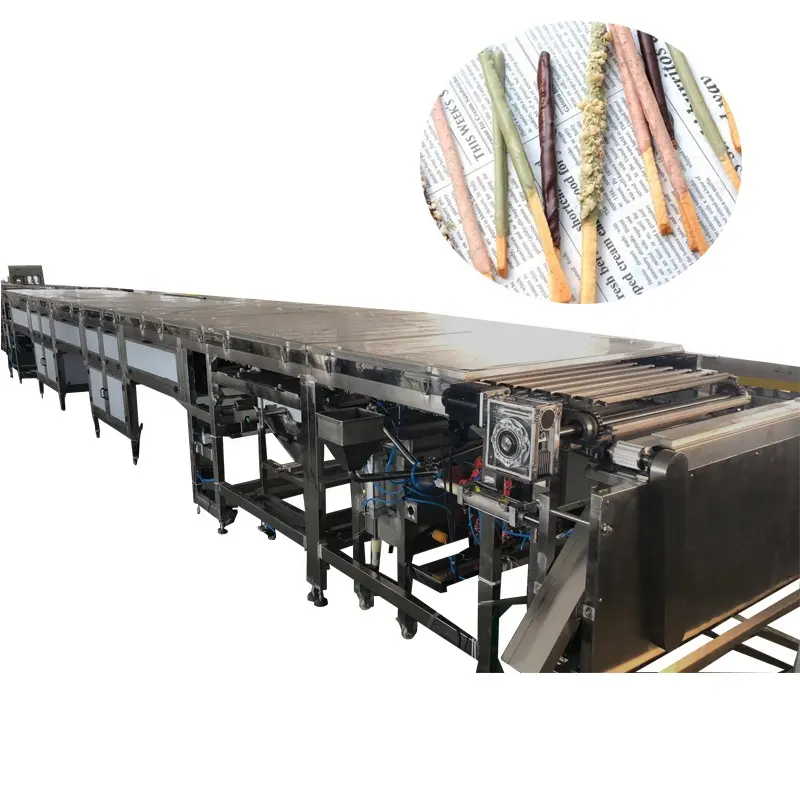

Finger Biscuit Chocolate Enrober Machine

Short Description:

The finger biscuit coating production line refers to an automated production line specifically designed for surface coating (such as chocolate, sugar coating, yogurt coating, etc.) on Ladyfings/Savoiardi or other similar elongated biscuits.

The chocolate finger biscuit production line usually includes multiple processes, with the design goal of efficiently, hygienically, and uniformly completing the coating and subsequent processing. The following are the main components and functions of a typical finger biscuit coating line:

1. Feeding/Feeding System:

*Function: orderly and smoothly feed the finger cookies to be coated into the production line.

*Forms: vibrating feeding tray, flat belt conveyor, inclined conveyor belt, etc. It is necessary to ensure that the direction of the cookies is consistent to prevent accumulation or damage.

2. Coating machine (core equipment):

*Function: Apply melted coating material (most commonly chocolate, but may also be candy coating, yogurt coating, syrup, etc.) evenly onto the surface of the cookie.

*Main types:

*Waterfall coating machine: Biscuits pass through a chocolate waterfall on a conveyor belt, and a molten coating is poured down from above to cover the top and sides of the biscuits. The bottom is usually not coated.

*Immersion coating machine: Biscuits are fully immersed in a tank containing a molten coating before being lifted. This can cover the entire surface (including the bottom), but precise control of immersion depth and time is required, and the bottom coating may be thicker.

Finger cookie coated wire key components:

*Coating tank/container: stores and heats molten coating materials.

*Temperature control system: Accurately control the temperature of the coating material (temperature regulation is particularly critical for chocolate).

*Pumping system: Circulating the coating material to the shower head/immersion tank/nozzle.

*Shower head/immersion wheel/spray arm: a device that performs coating.

*Bottom recycling tray: Collect dripping coating materials, filter them, and recycle them.

*Vibration device (optional): Gently vibrate the conveyor belt after coating to help remove excess coating and make the surface smoother.

3. Cooling tunnel:

*Function: Allow the coating to cool and solidify quickly and uniformly, forming a stable shell.

*Structure: A long tunnel with a cooling system (usually cold air circulation).

*Key parameters: temperature (usually 0-15 ° C depending on the coating material), humidity (low humidity to prevent frosting), wind speed, tunnel length/passage time. It is necessary to ensure that the coating is completely solidified before proceeding to the next process.

5. Secondary decoration/sprinkling system (optional):

*Function: Sprinkle decorative items (such as crushed nuts, sugar granules, colored sugar needles, coconut shreds, etc.) on the surface before the coating fully solidifies.

*Location: Usually between the coating machine outlet and the cooling tunnel inlet.

*Equipment: vibrating feeder, drum feeder, etc., in conjunction with measuring devices.

Product detail pictures:

| Model | 400 | 600 | 900 | 1200 |

| Belt width(mm) | 400 | 600 | 900 | 1200 |

| Belt speed(m/min) | 1-10 | 1-10 | 1-10 | 1-10 |

| Cooling tunnel length(m) | 10 | 14 | 20 | 24 |

| Refrigerating unit(set) | 2 | 3 | 4 | 5 |

| Tunnel temperature(°C ) | 2-10 | 2-10 | 2-10 | 2-10 |

| Total power(kw) | 12.1 | 20.8 | 23.8 | 27.8 |

| Weight(kg) | 2000 | 2450 | 3400 | 4100 |

| Dimension(mm) | 14200x950x1800 | 18200x1150x1800 | 24200x1450x1800 | 28250x1750x1800 |