China Industrial Biscuit Chocolate Enrobing Dipping Coating Machine Enrober For Donut

Short Description:

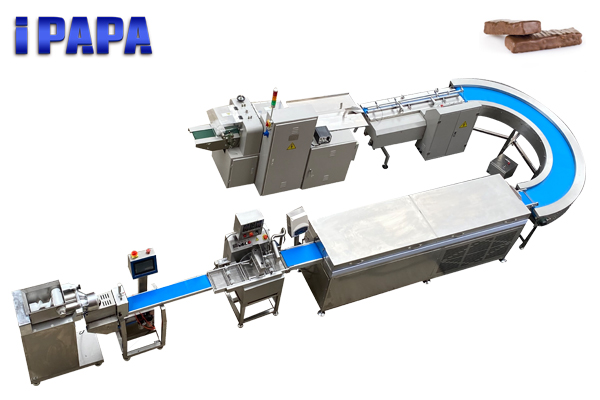

The finger biscuit coating production line refers to an automated production line specifically designed for surface coating (such as chocolate, sugar coating, yogurt coating, etc.) on Ladyfings/Savoiardi or other similar elongated biscuits.

What is a chocolate coating production line for finger cookies?

The finger biscuit chocolate coating production line is an automated chocolate processing system designed specifically for long strip biscuits (such as Ladyfinger and Baiqi biscuits). It adopts a surface coating process and is equipped with a 10 meter cooling tunnel, which can efficiently complete the entire production process of biscuit transportation, chocolate coating, cooling and solidification, and finished product packaging. This device is widely used in industries such as baked goods, snacks, and chocolate products, and is suitable for various coating requirements such as dark chocolate, milk chocolate, and white chocolate.

1. Biscuit arrangement: Automatic feeding ensures even spacing

2. Chocolate coating: Liquid chocolate forms a uniform curtain covering the surface of the biscuit

3. Cooling and shaping: A 10 meter cooling tunnel (2 minutes) allows the chocolate to quickly harden

4. Quality inspection: Visual system eliminates defective products

5. Packaging preparation: Output to the packaging machine or the next process

Technical advantages

-Leading in the 10 meter cooling tunnel industry:

-More thorough cooling than conventional 6-8 meter equipment, avoiding chocolate frosting (surface white spots)

-Crystallinity increased by 40%, resulting in better glossiness and taste of the product

-Intelligent temperature control system:

-± 0.5 ℃ accuracy, suitable for temperature regulating chocolate process

-Energy saving design:

-Heat recovery device reduces energy consumption by 30%

| Comparison item | This device | Conventional device |

| Cooling effect | 10 meter three-stage design | 6-8 meter single temperature zone |

| Coating uniformity | 10 meter three-stage design | Manual experience adjustment |

| Failure rate | <1% (annual) | 3-5% |

| Chocolate utilization rate | ≥ 95% | 85-90% |

This chocolate coating machine, with its 10 meter professional cooling tunnel and intelligent design, is significantly superior to similar equipment in the market in terms of coating uniformity, product quality, and energy consumption control. With a comprehensive after-sales service system, we can help customers quickly achieve mass production of high-quality chocolate cookies.

Product detail pictures:

| Model | 400 | 600 | 900 | 1200 |

| Belt width(mm) | 400 | 600 | 900 | 1200 |

| Belt speed(m/min) | 1-10 | 1-10 | 1-10 | 1-10 |

| Cooling tunnel length(m) | 10 | 14 | 20 | 24 |

| Refrigerating unit(set) | 2 | 3 | 4 | 5 |

| Tunnel temperature(°C ) | 2-10 | 2-10 | 2-10 | 2-10 |

| Total power(kw) | 12.1 | 20.8 | 23.8 | 27.8 |

| Weight(kg) | 2000 | 2450 | 3400 | 4100 |

| Dimension(mm) | 14200x950x1800 | 18200x1150x1800 | 24200x1450x1800 | 28250x1750x1800 |